1. Introduction:

Industries like petrochemicals, power generation, and heat treatment often operate under extreme temperatures. Traditional steel or inferior-grade stainless steel sheets fail prematurely under these harsh conditions—leading to frequent maintenance, safety risks, and increased operational costs. The need for a high-temperature resistant, corrosion-proof, and durable material is critical.

2. Product Introduction:

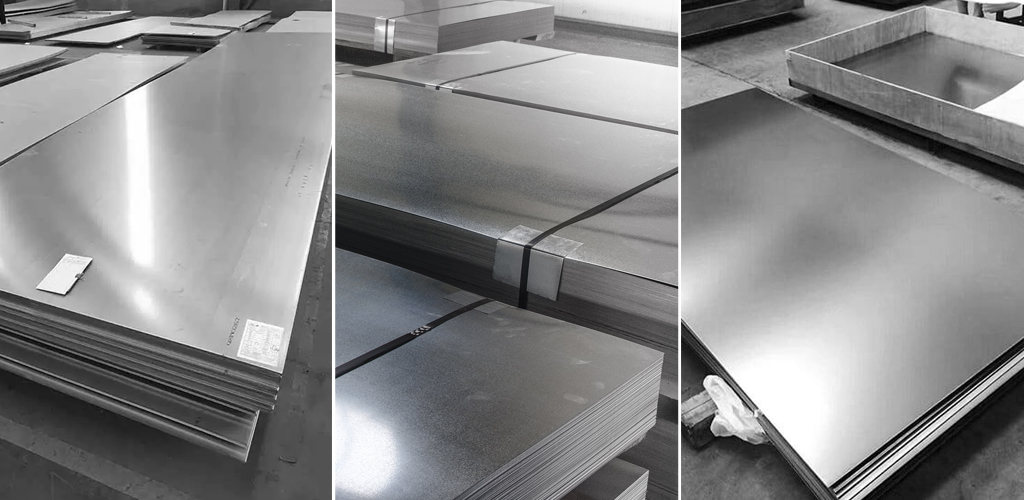

Stainless Steel 310 Sheets are high-alloy austenitic stainless steels designed specifically for elevated temperature service. These sheets are made in compliance with industry-recognized standards such as ASTM A240 and ASME SA240, ensuring durability, reliability, and superior performance.

They are composed primarily of chromium (25%) and nickel (20%), which provide outstanding oxidation resistance and mechanical strength even at temperatures up to 1150°C (2102°F).

Leading Stainless Steel 310 Sheets Suppliers and Stainless Steel 310 Sheets Stockists ensure that these materials are readily available in a variety of sizes, finishes, and specifications.

3. Key Advantages of Stainless Steel 310 Sheets

High Temperature Resistance: Maintains strength and structural integrity up to 1150°C.

Excellent Oxidation Resistance: Ideal for environments exposed to air and oxidizing gases at high temperatures.

Corrosion Resistant: Performs exceptionally well in mild cyclic environments and chemical exposure.

Superior Weldability & Fabrication: Can be easily welded, formed, and machined.

Long Service Life: Reduced maintenance and operational downtime.

4. Real-Life Applications

Stainless Steel 310 Sheets are widely used across industries such as:

Petrochemical Plants: Used in reformers, radiant tubes, and flare tips.

Furnace Components: Ideal for heat treatment trays, jigs, and muffles.

Power Generation: Employed in superheater and reheater tubing.

Food Processing: Useful for continuous cooking ovens due to high oxidation resistance.

Cement and Steel Plants: Liners and burner tips where high-temperature durability is essential.

5. How They Solve Problems & Outcome

By switching to Stainless Steel 310 Sheets, industries have seen:

Reduced Equipment Failure: Less cracking, warping, or scaling under heat stress.

Cost Savings: Less frequent replacements and lower downtime improve operational economics.

Enhanced Safety: Stable performance at high temperatures lowers risk of breakdowns.

Regulatory Compliance: Meeting ASTM A240 / ASME SA240 standards means safer, more efficient systems.

Stainless Steel 310 Sheets Suppliers and Stockists play a critical role in providing traceable, certified material that meets project-specific needs.

6. Conclusion

Stainless Steel 310 Sheets are a premium solution for industries demanding high temperature and corrosion resistance. With trusted Stainless Steel 310 Sheets Suppliers and Stockists offering certified materials per ASTM A240 / ASME SA240 standards, businesses can rely on durability, performance, and peace of mind in extreme environments.